From feasibility to control, we turn granular data into actionable decisions that improve performance and reduce risk

Expert wastewater process insight powered by real-time monitoring

Bi-Zen helps water companies design smarter, commission faster, and operate more efficiently - using short-term sensor deployments and deep process expertise to unlock cost and compliance gains.

Core Services

Digital Flow & Load

Real-world data to support feasibility, AMP8 optioneering, and design validation.

Commissioning Support

Live insight to validate asset performance and support smoother handover

Treatment Optimisation

Short campaigns to stabilise processes, reduce energy use, and improve control.

Compliance Recovery (Rescue Sites)

Rapid diagnostics to uncover root causes and support failing sites.

Typical Clients | Real-time monitoring | Scoping Survey | Immediate Response | Process Analysis | |

|---|---|---|---|---|---|

Flow & Load | Consultancy | ||||

Commissioning | Contractor | ||||

Optimisation | Water Company | ||||

Process Rescue | Water Company |

The Installation

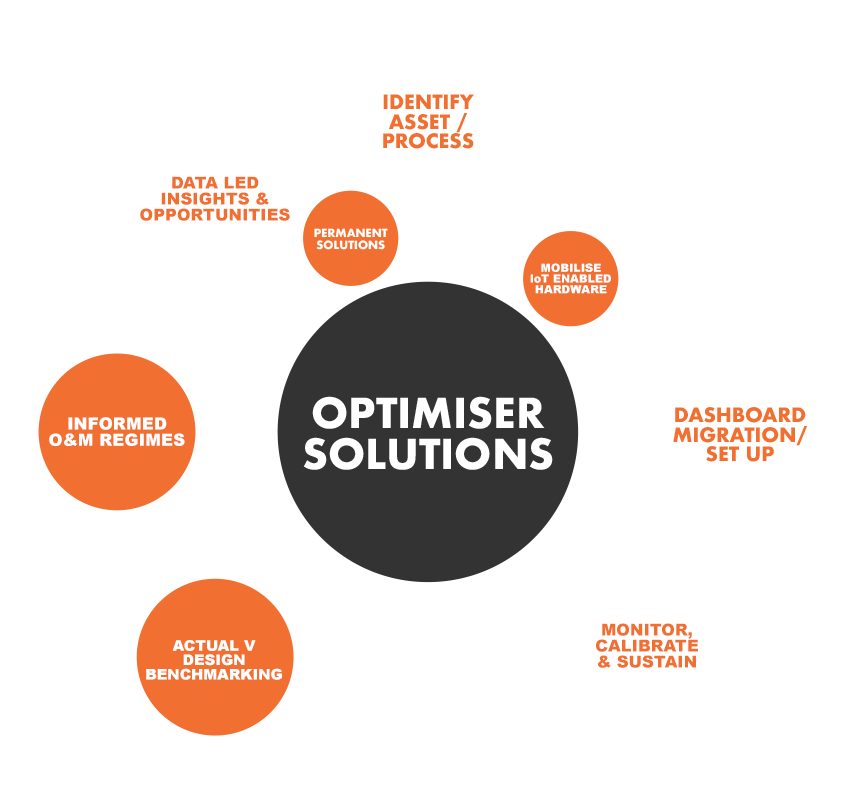

The optimiser is installed on site

With our sensors immersed in effluent

Data is transmitted off site as it is collected

Shared through a bespoke live dashboard that can be accessed via computer or smartphone

Flexible Engagement Models

BI-Zen supports both water companies and consultancies — offering flexible packages that fit your needs and complement your expertise.

Data & Insight Package

High-frequency monitoring with summary insights and recommendations. Ideal for clients or consultants who want robust evidence to guide internal teams.

Full Consultancy Package

Includes monitoring, insights, and direct process consultancy from our experts. Workshops, root cause analysis, optimisation planning, and ongoing support included.

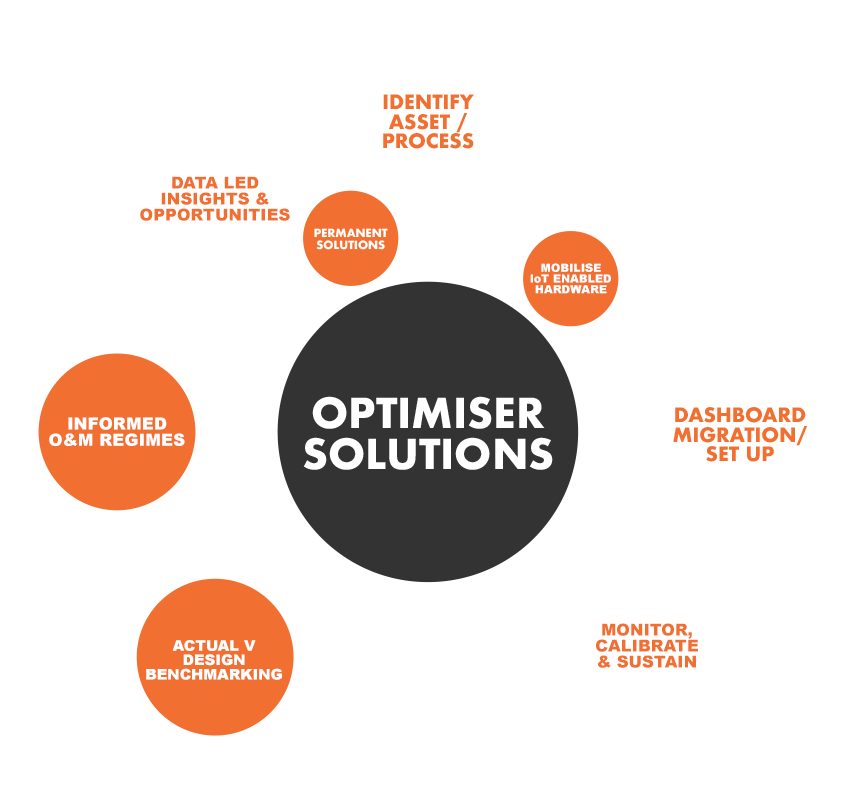

The Optimiser

Subject Matter Expertise

Data Provision

Our Approach Why It Works

Designed for Agility. Backed by Expertise. Built for Results.

We don't just monitor. We interpret, advise, and act-combining in-depth process understanding with high-resolution data to support confident informed decision-making across the full wastewater treatment lifecycle.

Contact Us

Why BI-Zen

- Trusted across AMP7 and AMP8 delivery

- Short-term deployments, long-term impact

- Enhances feasibility, commissioning, and ops

- Proven to reduce cost and carbon

- Partner to both asset owners and consultancies

- Expert-led, outcome-driven