The Optimiser

Subject Matter Expertise

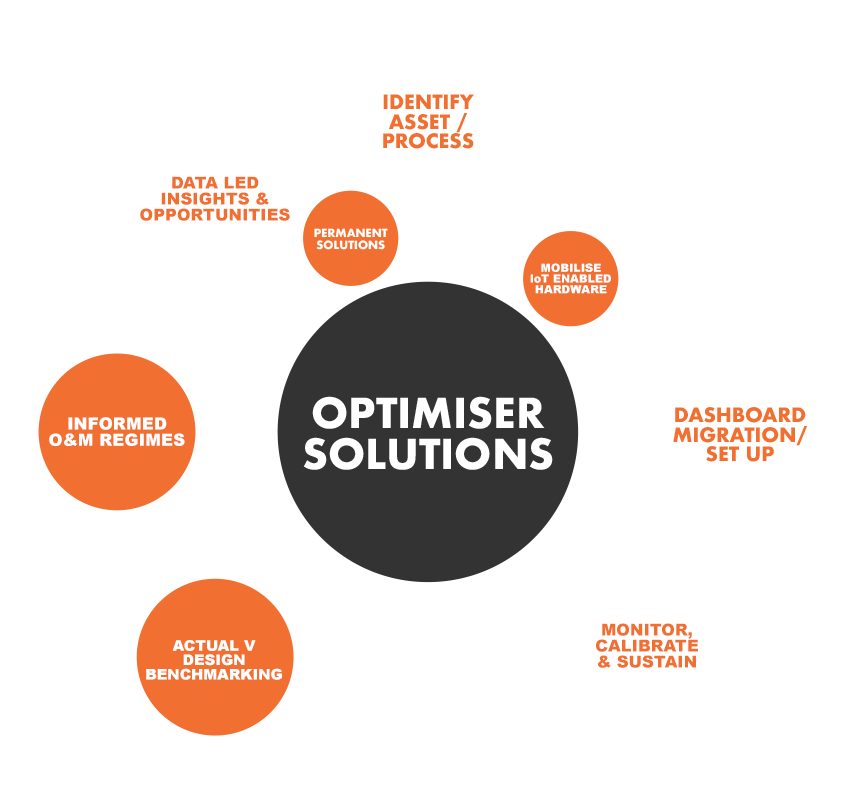

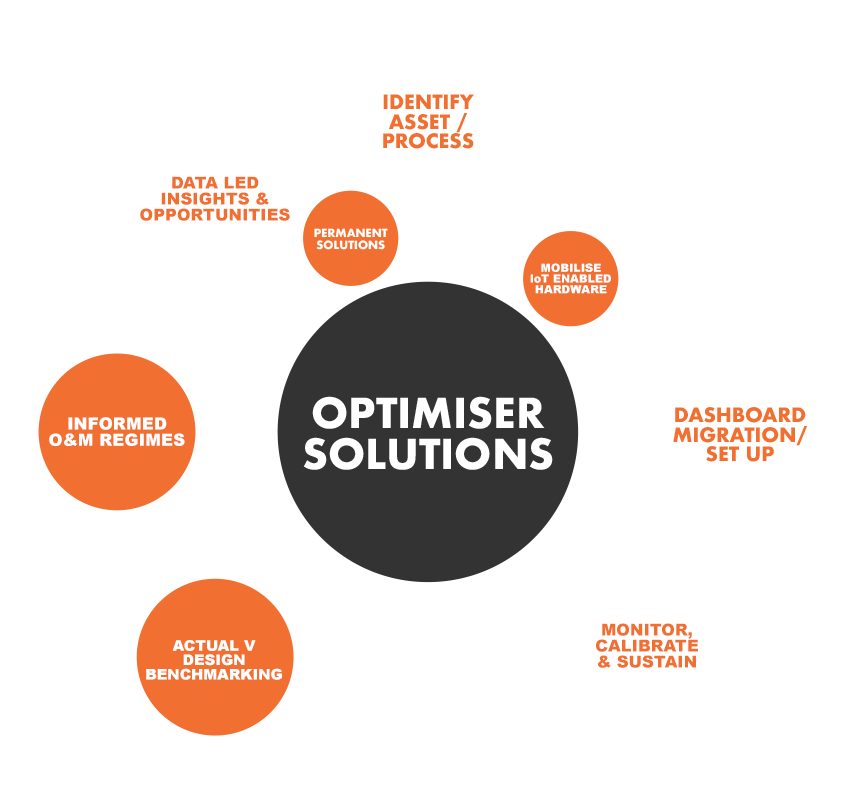

The Optimiser offers a smarter way of working, as Water Companies look to meet growth and capital investment challenges this AMP. Combing Hardware and Cloud based analytical Intelligence, promoting collaborative working.

Current monitoring systems provide data hours, days or even weeks after testing that prevents pro-active responses to changes. For example, the industry biochemical oxygen demand test takes five days to complete. This can lead to plants failing to meet compliance and incidents going undetected. Furthermore, current methods are often labour intensive and inaccurate.

With the Optimiser, real time monitoring of quality controlled essential determinants can provide a 400 to 1,200% increase in your data, when compared to the conventional sampling approach. Enabling clients to benchmark and optimise your wastewater treatment works at a granular level be that minute, hour, day or weeks.

A unique and proven solution for the real time monitoring of essential determinants, required for the benchmarking and optimisation of wastewater treatment works.

Contact Us

The robust, compact and durable units have been rigorously tested across various process locations including post-screened crude sewage, settled sewage and secondary treatment, to ensure the measurement does not drift under the most challenging process conditions.

The package enables clients to see live liquor concentrations at key points in the process, as well as providing the capability to integrate other data sets already measured by the client such as flow, compliance monitoring determinants and site power consumption. The Optimiser unit has been developed to enable rapid swap out of sensors, with the standard offering consisting of: COD, Ammonium, Turbidity, Nitrate, Redox, pH and temperature. This suite allows the system to inform the process operator on the sites operating envelope and potential stress points.

The data is live and continuous which enables the system to detect events which a standard composite sampling system may miss, leading to an incomplete picture of site loading and process performance.

The data gives the potential to identify and evaluate:

The Optimiser adds significant value over a conventional sampling programme, as the service offering will facilitate an increased visibility of process issues, performance, biological loading rates, as well as leverage optimisation opportunities, all at a lower cost than the conventional sampling programme.