Greater visibility of asset operation using data from instrumentation.

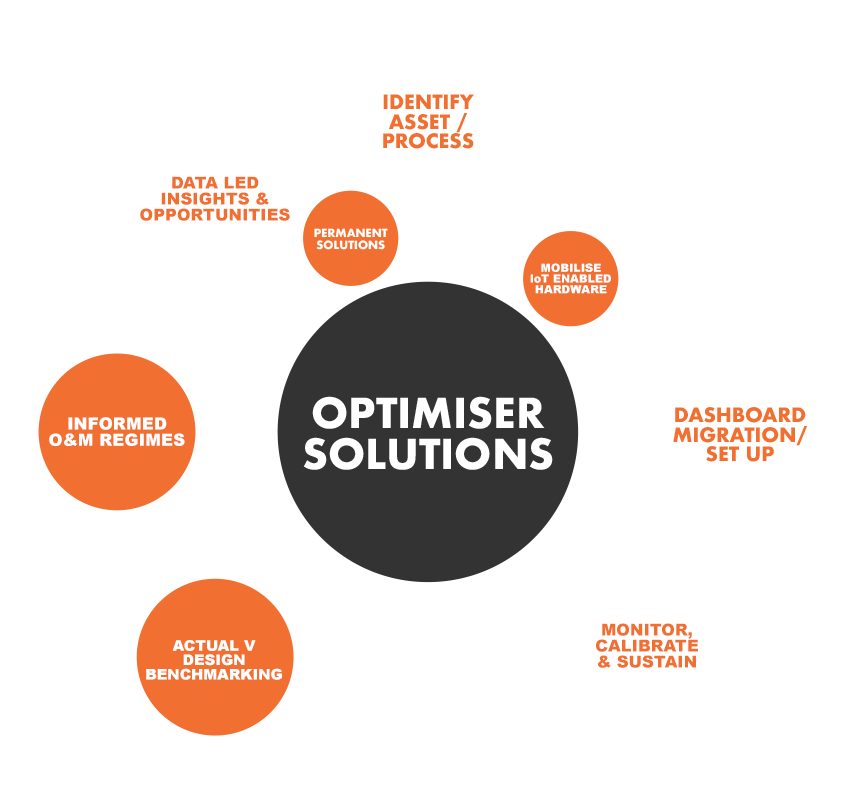

This blog highlights the “digital approach” over the conventional manual data capture methodologies. Summarising why BI-Zen uses a combination of cloud analytical tools, process subject matter expertise and existing data, supplemented with multi-parameter IoT enabled instrumentation. To provide our clients with the right level of information to make informed decisions, leading to CAPEX and OPEX savings.

Process Data The water sector contains vast asset standards and process monitoring data sets. However, confidence in some sensor data can be limited, reducing its value, if assets are not correctly data mapped, routinely maintained and calibrated. There are also gaps with many sites that do not have comprehensive data on influent as well as settled sewage conditions needed to inform on process demand and operational control needs.

As a result, process evaluation surveys typically utilise a set of lab data derived from discrete or spot samples, which can miss key events and provide an incomplete picture of plant operation. Further still, conventional process evaluations can be limited to “static excel optimisation” limiting the ability to conduct a holistic evaluation of the works, increasing the risk of missed opportunities as well as leading to conservatism in design and operation.

Sensor development It is well understood that influent wastewater can be a harsh environment, containing rag, fats and oils. These contaminants can quickly reduce sensor accuracy impacting on the generated data quality that has historically limited the uptake of sensor application for routine measurement of wastewater influent characteristics. The material can also block conventional sampler hoses, with the potential to compromise reliable capture of a representative sample.

In recent years sensors have become more reliable when incorporating effective air clean and focused quality controls, leveraged with access to the live data, via IoT applications. Now reliable digital data sets of the crude and settle sewage make-up can be gained, unlocking new insights into our understanding of wastewater treatment. This opens the potential to obtain granular rich data sets of the actual chemical make-up of the material entering works for treatment processing.

Process insights With the right level of temporary IoT enabled sensor data, a cost effective and disruptive approach to the conventional quantification of a works actual performance can now consider the application of sensors over manual time limited sampling programmes. With reliable sensor data, an assessment of the actual performance can be used to make informed challenges over the theoretical and technical design optioneering. It also assists to inform on the potential to defer or cease any capital investment, in favour of identified OPEX and operational control.

Please check out our case studies page as well as follow us on our LinkedIn profile for more details on how BI-Zen is helping its clients leverage more from their assets through its digital F&L service offerings.